Bradley Forged Takumi Matte Titanium Bronze 17″ 6×139 et -15 Genuine

Original price was: ₱200,000.00.₱194,998.00Current price is: ₱194,998.00.

SET OF 4

Additional information

| Brand | BRADLEY |

|---|

Description

Description

BRADLEY FORGED TAKUMI

SET OF 4

The strongest BRADLEY ever created by master craftsmen. 4×4 Engineering Service has unleashed a supreme forged 4WD wheel.

The pinnacle of BRADLEY. Forged wheels made with all our strength.

The development of the FORGED TAKUMI began long before the BRADLEY V was tested without tires. It took time and money to develop a flagship model that would surpass the BRADLEY V, which was regarded as the world’s strongest.

In the world of XC competition, it is not a simple matter of “forged is better” or “cast is worse”. What is important is how you drive and what you need to drive.

We have taken over the competition concept of the BRADLEY V without losing a single millimeter, and have met the expectations of BRADLEY fans who have continued to support us for over 30 years. To live up to the name of “XC fanatics”, we’ve put our heart and soul into this forging.

Its true value will be proven in future races, and a new history of BRADLEY will be built.

Japan’s most advanced forging technology

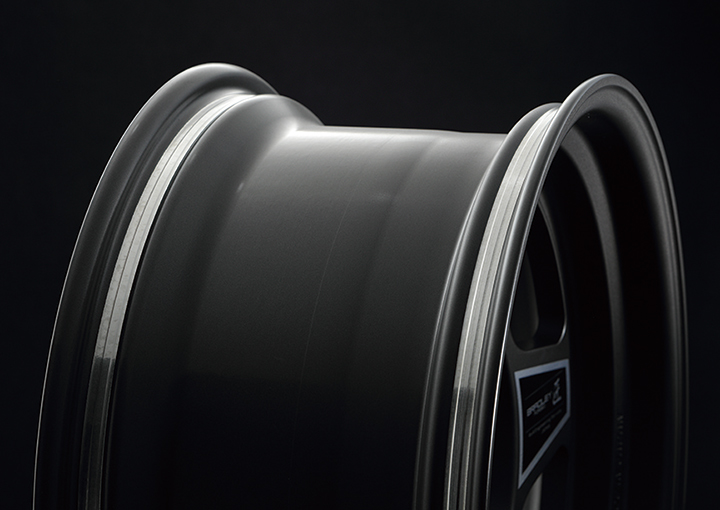

The FORGED TAKUMI uses the forging technology of TAN-EI-SYA, which has a rare 8,000-ton hydraulic press machine that supports the world’s racing scene. By applying enormous pressure to the aluminum alloy, the metal structure is made dense and uniform, ensuring high strength and rigidity. The rim is formed using the tear-open method, in which the material is rolled while being torn by rollers, to forge it thinly and achieve both high strength and light weight.。

In addition, all surfaces of the design are machined using a machining center and a variety of proprietary tools to ensure high precision without any residual stress distortion.

This is exactly the kind of manufacturing process that is best suited for our flagship competition model.

Focus on functions for tough running performance

All sizes come standard with anti-bead-slip finish that prevents shifting both horizontally and vertically.

By adding 4mm wide convexes to both ends of the bead seat where the tire and wheel are installed, and deliberately leaving the machining area unpainted, the bead is less likely to fall off even when running on lock at low air pressure.

This prevents bead slippage (tire spinning) when a large amount of rotational torque is applied momentarily.

Rubber valves are standard equipment because of the competition concept.

On rocky ascents, there are cases where the valve comes into contact with the rock, and steel or aluminum valves may break, causing problems for the rider.

Focus on fitting that combines functionality and beauty.

Specially designed for each car model, forged materials are reviewed and optimized from the mold up.

The RADLEY FORGED TAKUMI is not only designed specifically for each car model, but has also been redesigned from the material mold, which is the basis of the forging process, to ensure the optimum cross-sectional approach, clearance, and wall thickness for each car model.

This is a non-negotiable concern for XC enthusiasts who know that even a small difference of 1mm can determine the outcome of a race.

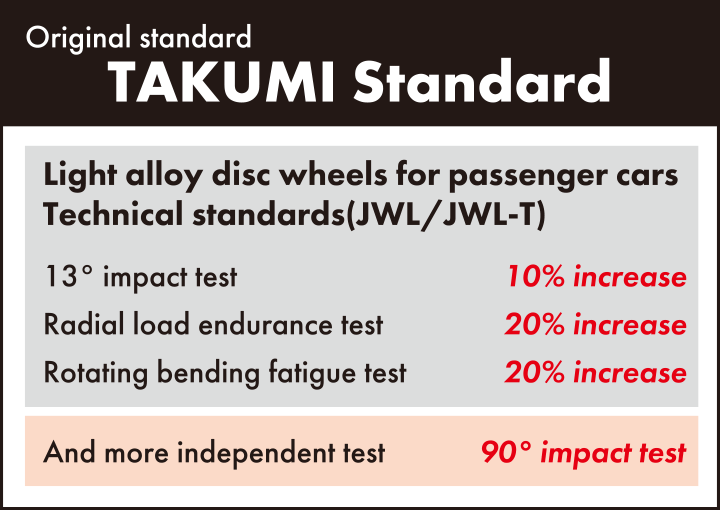

A commitment to quality that exceeds standard technical standards

The “TAKUMI Standard” is a standard that surpasses the BRADLEY V, which is regarded as the world’s strongest.

The BRADLEY FORGED TAKUMI has set a standard that is 10 to 20% higher than the Japanese government’s technical standards for passenger car light alloy disc wheels (JWL/JWL-T), and has also added its own strength test. This rigorous strength evaluation test is daringly regarded as a standard and named “TAKUMI Standard”. It provides high strength and rigidity to satisfy the hard driving needs of XC enthusiasts.

[JWL/JWL-T] 13-degree impact test: strength test assuming impact with a curb, etc.: 10% increase

[JWL/JWL-T] Radial load endurance test: Endurance test assuming upward and downward load applied while driving straight ahead: 20% increase.

[JWL/JWL-T] Rotating bending fatigue test: Fatigue test assuming lateral load applied to wheel during cornering: 20% increase

[Independent test] 90-degree impact test: Fixed with tire mounted, 1 ton impact applied to inner rim.

An additional test unique to 4×4 Engineering Services to confirm the strength of the inner rim, which is susceptible to impact.